Research and development, production, and sales of intelligent equipment for automatic welding machine.

Case Study: Successful Implementation of Projection Welding Machines

Projection welding machines have emerged as a game-changer in various industries, offering precision and efficiency that were previously unattainable. These machines are particularly useful in industries where high-quality welds are essential, such as automotive, aerospace, and manufacturing. In this case study, we explore the transformative impact of projection welding machines, focusing on a specific automotive industry that faced challenges before implementing these machines.

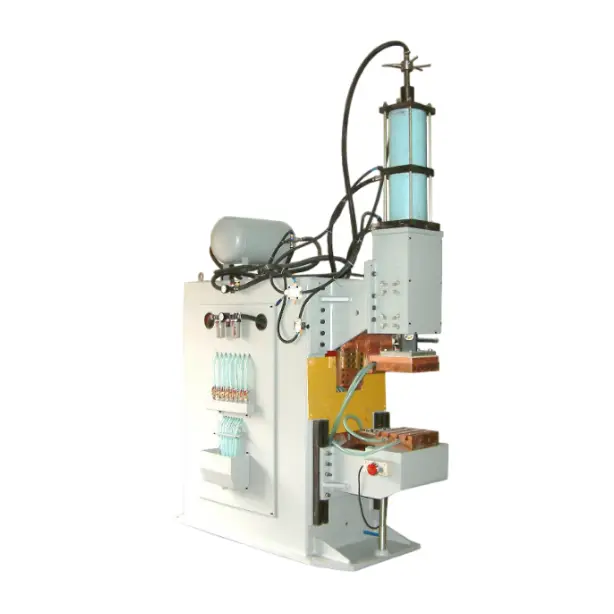

Projection welding machines are advanced tools that use a moving torch to project a focused beam of heat onto a workpiece, creating a weld pool. This method is ideal for thin and delicate materials, making it superior to traditional welding techniques in terms of accuracy and consistency. The growing demand for precision in manufacturing has made projection welding a popular choice for industries seeking to enhance their processes.

Take the automotive industry, for instance, where the complexity of modern vehicles requires flawless welds. Traditional welding methods often struggle with thin components, leading to inconsistencies and potential failures. A car manufacturer faced these exact challenges, with parts like engine bay rails and door panels proving difficult to weld accurately. When the company decided to invest in projection welding machines, it marked the beginning of a paradigm shift in their manufacturing operations.

Case Study Overview: From Challenges to Solutions

The automotive company in question struggled with welding thin, intricate parts, which often resulted in subpar quality and inefficiencies. The machine's inability to handle these components effectively weighed heavily on the company's productivity and product standards. The management recognized the need for a more reliable solution and approached a technology vendor specializing in projection welding. After a thorough evaluation, the company selected a high-end projection welding machine known for its precision and durability.

The installation process was meticulous, with the vendor ensuring the machine was tailored to the specific needs of the company's workshop. The initial setup required adjusting the machine's parameters to accommodate the unique geometry of the parts being welded. The vendor also provided comprehensive training for the team, ensuring that operators were adept at using the new technology.

Technical Considerations: Understanding Projection Welding Process

The projection welding process involves projecting a focused beam of heat onto a workpiece, creating a weld pool. This method is particularly effective for thin materials, where it ensures even heat distribution and precise welds. The machine's design includes a torch that projects the heat beam, guided by a lens to focus the weld pool accurately.

There are two main types of projection welding: contact and friction projection welding. Contact welding uses a consumable electrode to create the weld pool, while friction welding relies on friction between the torch and the workpiece. The choice between the two depends on the material being welded and the specific application.

The machine's specifications, including the size of the heat beam, the speed of the torch, and the cooling system, play a crucial role in its performance. Proper tooling and sensor integration are also essential, as they ensure the machine operates smoothly and maintains precision.

Benefits Realized: Improvements Through Implementation

The implementation of projection welding machines brought about significant improvements in the automotive company's operations. One of the most notable benefits was the marked increase in weld quality. Traditional welding methods often resulted in splintered welds, which were difficult to inspect and prone to failure. With projection welding, the welds were seamless and free from defects, significantly improving the overall quality of the components.

Efficiency was another key benefit. Projection welding machines can handle multiple passes in a single operation, reducing the time required for each weld. This not only increased productivity but also minimized downtime, allowing the company to meet tighter deadlines. Cost savings were also realized through reduced material waste and lower rework costs, which translated into significant financial benefits for the company.

Integration and Training: Ensuring Smooth Transition

The integration of projection welding machines into the company's workflow was seamless, thanks to proper planning and execution. The vendor ensured that the machine was aligned with the existing production line, with minimal downtime. The training program was comprehensive, covering everything from machine operation to advanced troubleshooting. Operators were provided with detailed manuals and access to online resources, ensuring they were fully prepared to use the new technology.

Ongoing support was also a key component of the transition. The vendor offered regular maintenance checks and provided assistance in addressing any issues that arose during the operation. This level of support was crucial in ensuring the machine's reliability and performance over the long term.

Comparative Analysis: Traditional vs. Projection Welding

A direct comparison between traditional welding and projection welding revealed clear advantages of the latter. Traditional welding methods often resulted in welds that were difficult to inspect, with inconsistencies in thickness and shape. Projection welding, on the other hand, provided welds that were uniform and precise, making them easier to inspect and ensuring higher quality standards.

Performance metrics such as weld strength, consistency, and reliability were also superior with projection welding. The machine's ability to handle thin materials with ease resulted in welds that were stronger and more durable than those produced by traditional methods. This not only improved the quality of the final product but also reduced the likelihood of post-weld issues.

Future Outlook: Advancing with Projection Welding Technology

The future of projection welding looks promising, with ongoing advancements in technology opening new possibilities for industries. Emerging trends include the integration of AI and machine learning to optimize welding parameters, the development of more efficient machines, and the expansion into new applications such as 3D printing and additive manufacturing.

The growing emphasis on sustainability and environmental responsibility is also driving innovation in projection welding. New machines are being developed with lower energy consumption and reduced emissions, making them more appealing to environmentally conscious industries. The use of projection welding in renewable energy applications, such as solar panel manufacturing, is another exciting development.

Successful Implementation of Projection Welding Machines

The successful implementation of projection welding machines has had a profound impact on the automotive industry, transforming their approach to welding and opening new possibilities for efficiency and quality. The initial challenges faced by the company were overcome with the right technology and support, leading to significant improvements in both production and product quality.

As projection welding technology continues to evolve, its potential to revolutionize manufacturing and other industries is clear. By embracing this technology, companies can unlock new levels of efficiency, precision, and sustainability. The automotive industry sets a strong example of the transformative power of projection welding, inspiring other industries to explore and adopt this technology for better results.

In conclusion, the integration of projection welding machines into the automotive industry was a pivotal moment in their journey towards excellence. The lessons learned from this case study highlight the importance of innovation and the potential for projection welding to shape the future of manufacturing. Encouraging other industries to embrace this technology can lead to similar breakthroughs and set new standards for quality and efficiency.