Research and development, production, and sales of intelligent equipment for automatic welding machine.

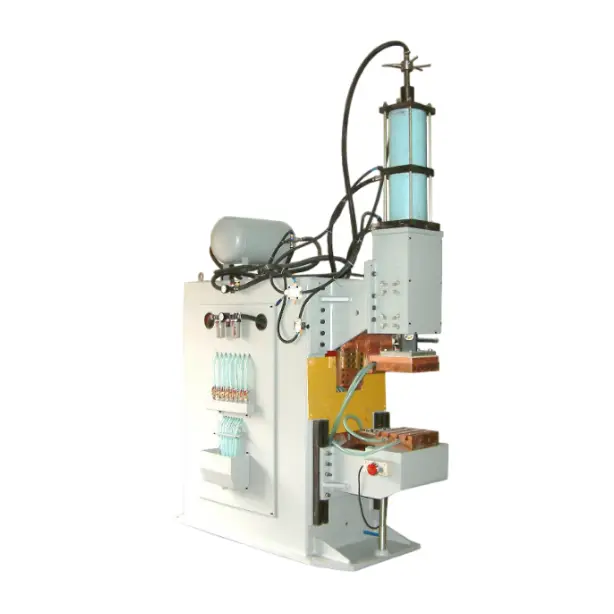

Projection Welding Machine Budget Friendly Options: Saving Money on High-Tech Solutions

Navigating the Price Landscape

Determining the right projection welding machine can be as complex as the welding process itself. Several factors come into play when setting prices. These include the machine's complexity, the quality of its components, and its precision requirements. Cost components such as motors, heating elements, and control systems significantly impact the overall price. Understanding current market trends is key. Recent advancements in energy efficiency and automation have made budget-friendly options more desirable without compromising on performance.

Finding the Right Fit: Budget-Friendly Models Unveiled

Investing in a budget-friendly projection welding machine doesnt mean compromising on quality. Entry-level models offer robust features that ensure reliability and efficiency. Mid-range options come with smart controls and energy-efficient designs, reducing long-term operational costs. The key lies in understanding what's essential for your manufacturing process. These machines offer substantial cost savings by minimizing maintenance needs and reducing overall operational expenses.

Head-to-Head: High-End vs. Budget

While high-end projection welding machines boast advanced features like AI integration and multi-axis controls, budget-friendly models deliver impressive performance at a lower cost. Mid-range options typically include smart controls and energy-efficient designs, enhancing reliability and efficiency. Real-world examples like the European automotive manufacturer that reduced production time by 20% and the aerospace company that cut manufacturing costs by 15% demonstrate the tangible benefits of budget-friendly machines.

Lessons from the Best: Success Stories That Speak Volumes

Several businesses have successfully integrated cost-effective projection welding machines, achieving remarkable results. A European automotive manufacturer, for instance, reduced production time by 20% by upgrading to a mid-range model, significantly boosting efficiency. Another company in the aerospace industry cut manufacturing costs by 15% by implementing a budget-friendly model, improving competitiveness. These success stories underscore the undeniable benefits of budget-friendly solutions and provide actionable insights for other manufacturers.

Innovations in Motion: Embracing Advanced Technologies

Recent advancements in budget-friendly projection welding machines include smart controls, AI integration, and innovative materials. These technologies improve functionality without increasing costs, making machines more versatile and efficient. For example, AI-driven systems can optimize welding parameters, reducing downtime and improving accuracy. Smart controls allow for remote monitoring and maintenance, further enhancing operational efficiency. These innovations position budget-friendly machines as powerful tools for modern manufacturing.

Choosing Wisely: Tips for Optimal Selection

Selecting the appropriate projection welding machine requires careful consideration of specific needs. Key questions include the desired precision, expected lifespan, and available maintenance support. Evaluating features like smart controls, energy efficiency, and durability is essential. Checking the manufacturer's reputation and warranty can also be beneficial. A checklist can help readers assess machine suitability, ensuring they choose a model that aligns with their operational requirements.

A Call to Action

Projection welding machines are essential for efficient manufacturing, and budget-friendly options offer a cost-effective solution without compromising quality. By exploring features, comparing models, and learning from success stories, businesses can make informed decisions. Budget-friendly machines not only reduce costs but also enhance productivity, making them a viable alternative to high-end solutions. As technology evolves, budget-friendly models are becoming more sophisticated, providing businesses with powerful tools to stay competitive. For further insights, resources on the topic are available for deeper exploration.