Research and development, production, and sales of intelligent equipment for automatic welding machine.

New Welding Solution Company

Product details of the welding solution

Quick Overview

Hanyan Welder welding solution adopts imported raw materials to ensure the smooth production process. The product is functional and with an internationally certified quality. To prepare an anode combining the excellent properties of tantalum at reasonable price, a new material has been developed in our laboratory.

Product Description

Compared with other same kind of products in the market, Hanyan Welder's welding solution is equipped with the following outstanding advantages.

Brief Introduction Of Products

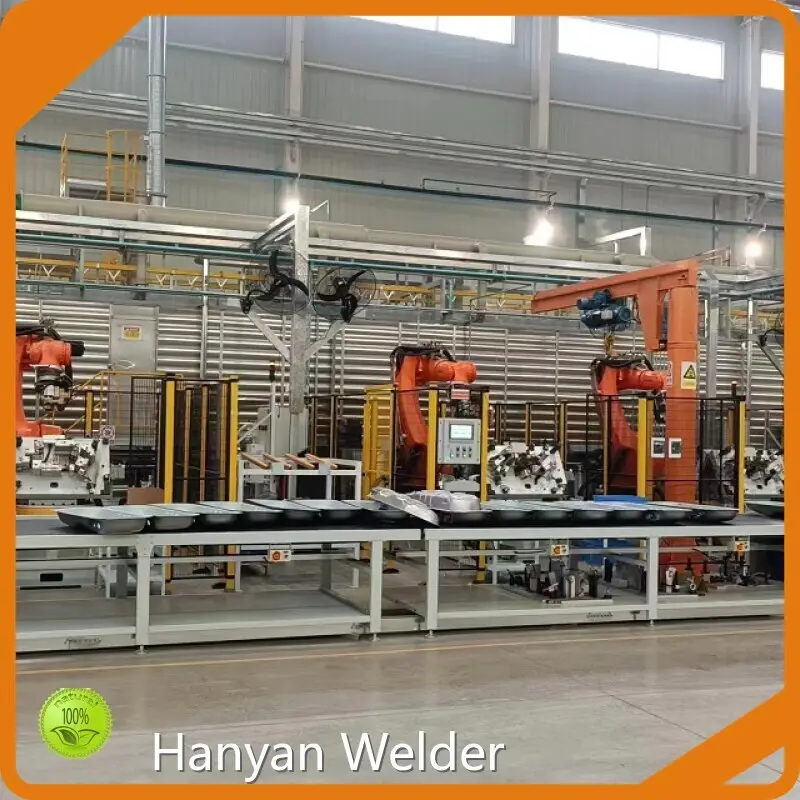

Automatic welding production line, suitable for various types of metal fuel tanks of automobiles, including automatic robot resistance seam welding of automobile fuel tank , automatic robot resistance spot welding of fuel tank accessories, and robot arc welding workstation of fuel tank filler . Through the automatic logistics car and logistics robot to achieve the production line automatic logistics.The whole line is highly automated to achieve unmanned automatic processing and production. Design special welding fixture for different types of fuel tanks.

Product Strengths And Characteristics

1.The production line adopts bus technology for control, integrating press fit special machines, robot handling, and robot welding, with high automation, improving efficiency, and greatly reducing personnel labor intensity;

2.Integrated with imported high-precision laser welding real-time tracking system, ensuring that the equipment can weld high-quality products even when there are changes in the workpiece;

3.Adopting the most advanced CMT welding technology in the industry to achieve high-speed splash free welding;

4.The modular fixture design pattern facilitates changeover and adapts to the production of different specifications of products to meet the flexible production needs.

5.The fixture positioning drive adopts a servo system and external grating for closed-loop control, with high positioning accuracy;

6.An independent security unit ensures the safe operation of the equipment;

7.The single piece production cycle time is less than 210 seconds, which increases the production efficiency by 200% compared to traditional methods. The first pass rate of the product is greater than 95.

Application Fields

The automated welding line is widely used in enclosures, such as car and motorcycle fuel tanks; Seam welding of barrel bodies, such as oil drums, and formed sheet metal workpieces, such as wheel rims, mufflers, radiators, etc.

Company Advantages

Based on outstanding ability in developing and manufacturing of welding solution, Chengdu Hanyan Tec Robot Co., Ltd. goes far ahead of the industry. Chengdu Hanyan Tec Robot Co., Ltd. has a complete and scientific quality management system. Hanyan Welder desires to be one of the most leading enterprise in welding solution industry.

Look forward to working with you to create a better future.